Home Safer transportation of your products Spacers play an important...

Read MoreWireless temperature sensors

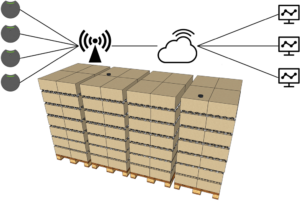

For wireless, real-time temperature readings in food production

All food processing, also freezing, thawing and tempering is temperature sensitive. Detailed, real-time knowledge of how temperature develops has great significance for the quality of your products and not least the costs involved in the process.

Learn more about temperature sensors in food production in this article.

Wireless data transmission in freezers

Traditionally it has been almost impossible to transmit data wirelessly from freezers as these often consist of steel construction which turns these into transmission-dead, “Faraday Cages” Faraday cages.

Consequently, temperature loggers are commonly used to document the freezing process although this retro-perspective information does not enable you to react instantly to any deviations.

Real-time sensors vs Passive loggers

Maintaining a consistent and appropriate temperature is crucial for the preservation and quality of the stored products. Often temperature loggers are used to document how the freezing process went, but temperature loggers don’t give you a real-time view of your freezing chamber.

Real-time temperature monitoring ensures that any temperature fluctuations or deviations are detected and addressed immediately, reducing the risk of product spoilage and improving product quality.

Improve food quality and improve operational profits

As FreezeTeq’s wireless temperature sensors are based on the well-proven Sigfox technology our sensors can in a unique way collect and transmit data wirelessly also under the challenging conditions of freezing and thawing.

The Ø 7 cm small sensor which operates on two interchangeable AA batteries has 2 measuring points – one inside the sensor plus an external one, where a wide range of different temperature probes can be connected through the standard K-connector.

The small size of the sensor combined with the connectable temperature probes provides unprecedented flexibility making it possible to place the sensors and measure temperatures in different places in your freezer – also inside the boxes. This helps improve the quality of your product and improve operational profits.

Want to know more about how you reduce your energy costs with real-time sensors?

Read more about capacity and product handling

About pallet inverters

Home About pallet inverters The benefits and process of using...

Read MoreAbout real-time sensors

Home Wireless temperature sensors For wireless, real-time temperature readings in...

Read More