Home Freezing strategies When blast freezing foodstuff there are basically...

Read MoreEfficient blast freezing with freezer spacers

Optimal airflow in blast freezing

- cooling device

- blasting

- evaporator

Here it all comes down to optimal airflow – between your pallets and box layers as in the freezing chamber.

As air will always choose the path with the least resistance, it prefers to go around your pallets.

As this only indirectly will cool/freeze the middle layers of your pallet stacks, the freezing will be unnecessarily long and expensive.

How do spacers enhance the blast-freezing process?

By inserting spacers between your box layers, you allow the air also to extract heat from the centre of your pallet stacks. And at the same time facilitating a better airflow in the entire freezing chamber.

Watch the video to learn how freezer spacers enhance the blast-freezing process.

Did you know?

Amongst others, VDKL (Verband Deutscher Kühlhäuser und Kühllogistikunternehmen – The German union of cold storage and logistics) highly recommends using spacers in blast-freezing processes.

Crucial factors to improve the blast freezing process

As you can imagine there are big differences between spacer designs. Minimal air resistance and support of your box layers are some of the crucial factors.

Let’s dive into the main factors that help you improve your blast-freezing process:

-

The unique, 50 mm high and supportive design of the FreezeTeq spacers provides minimal air resistance and facilitates as such maximum airflow in your freezing chamber.

-

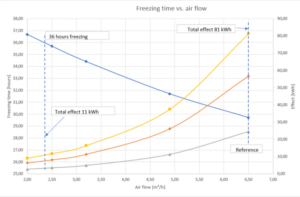

Not only reduces the time required to freeze your products, but also enables a lowering of the fan speed. This results in potential energy reductions of as much as 75% - and with that considerable cost savings.

-

The large and evenly distributed support area of the spacers also ensures that your boxes do not collapse and thus are damaged and block the airflow.

-

Last but not least the rigid design and high-quality HDPE material ensure a long life span and makes them suitable also for atomized handling.

Read more about our spacer models and learn which model can help you improve your blast-freezing process and reduce energy costs.

FreezeTeq spacer models

There are several solutions when you want to optimize your freezing operation. Have a look at our product selection and find the solution that’ll help you optimise efficiency and reduce your overall costs.

Contact

Learn more about the science behind freezing efficiency and process optimization

Blast Freezing Q&A

Home Blast Freezing Q&A Published as “Blast Freezing Tips” in...

Read MoreReduce energy cost with freezer spacers

Home Reduce energy costs with freezer spacers This may be...

Read More