Home Can freezer spacers be used for thawing? Although initially...

Read MoreWhat are freezer spacers?

Freezer spacers – how do they work

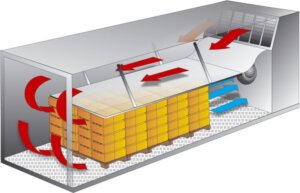

The overall purpose of using freezer spacers is to create space between the stacked layers. This is to transport the heat from the content within the stacked boxes – especially in the middle of the stacks where the cooled air otherwise would have limited contact. Let’s define this function as “heat-transfer”.

High air velocity across the product and maximum contact between the cold, high-velocity air stream and the product – in our case the stacked boxes – are both essential for high efficiency.

Our freezer spacers can also be referred to as “plastic pallets” as they are made from recycled High-Density Polyethylene. This makes them withstand temperatures between -50°C and +90°C and is resistant to acids and chemicals, ensuring a long lifespan. As for most product categories also freezer-spacers come in a variety of designs. As such it is not always easy to weigh the differences in-between these and determine which ones are best suited for your operation.

In this video you’ll learn some of the differences, and how our freezer spacers can help you improve your product quality and reduce your freezing time.

Improve your airflow

An important spacer function is to ensure that the cold air in your blast freezer is not blocked after the first few pallets but reaches the pallets at the far end of the freezing chamber. This function is defined as “airflow”.

High airflow throughout the freezing chamber is extremely important for the overall efficiency of the freezing process as the total batch-freezing time, after all, is determined by the “last sheep in the flock”. If the velocity of the air stream has dropped considerably after the first few pallets (which is not unusual) it’s easy to imagine how much “energy” there is left for the “heat transfer” from the pallets at the far end of the freezing chamber. Consequently, you risk wasting lots of energy on your cooling system, fans, and evaporators.

Accordingly, it is important for the efficiency of a spacer that air is not confined within the spacer in between the stacked layers but that the spacer is designed in a way that allows high air exchange. At FreezeTeq we believe in a 50 mm high, open profile spacer design – simply because this has proven its superior efficiency.

Did you know?

To minimize that air is “caught” in between the individual pallets, we recommend that the pallets are placed close to each other as possible. Thereby “forcing” the airstream to pass through the pallets rather than to turbo-lice in between these.

The functionality of freezer spacers

Functionality is as important as efficiency. After all – if the benefits do not exceed the drawbacks you would probably not use spacers at all. Functionality is determined by various factors such as:

- Support of the stacked boxes

- Stackability

- Rigidness

- Easy to clean

- Anti-slip surface

- Automated-/Robot-handling

- Weight

- Cost and life-time

There are big differences in blast-freezing operations and the way spacers are applied, the importance of the above features varies. Hence the efficiency of the spacer and the above features must be prioritized, evaluated and rated individually when investing in spacers.

What sets FreezeTeq spacers apart from other competitors?

Feedback from a wide range of companies indicates that FreezeTeq spacers outperform other alternatives. simply because the unique design facilitates a high airflow and the best support of the box layers.

Compared to cheaper alternatives, the gained efficiency improvements, easier handling and daily savings with FreezeTeq spaces quickly outweigh the small additional costs making this investment profitable year after year.

FreezeTeq spacer models

We have the right spacer model for your freezing operation. Have a look at our product selection and find the solution that’ll help you optimise efficiency and reduce your overall costs.

Contact us

Learn more about the science behind freezing efficiency and process optimization

Research and development

Home Research and development to improve freezing efficiency With 30...

Read MoreThe SOKI Project – Super Optimized Carton Freezer

Home The SOKI Project – Super Optimized Carton Freezer The...

Read More