Home Freezing strategies When blast freezing foodstuff there are basically...

Read MoreFreezing strategies

When blast freezing foodstuff there are basically two approaches – Speed or convenience.

The difference can be up to 80% in energy consumption

Speed or excellence?

When blast freezing foodstuff there are generally two basic freezing-strategies;

Capacity utilization

in which the products are aimed frozen as quickly as possible in order to fully utilize the capacity of the blast freezer

OR

Operational excellence

in which the company has a natural ”operational cycle” – perhaps with 24 or 36 hours shifts, after which the blast freezer is emptied and reloaded. Here the freezing-strategy is to match the freezing-time to such cycles.

And how is this of importance?

Well – it is obvious that shorter freezing time requires more energy, as the main driver for cooling products in your blast freezer is the combination of temperature and air-flow – both factors which require energy.

But did you know that the energy-consumption develops exponentially as air-flow is adjusted?

The explanation to this is that increased air/flow requires more energy to your fans and cooling unit. As the fans generate heat during operation increased fan-speed will require even more energy just to cool its own heat.

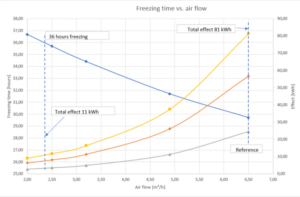

The general relation between air-flow, energy consumption and freezing time is illustrated in the graph on the right:

Data is derived from a test carried out in a rather effective 20” test-blast freezer.

Figures will of course vary in-between various blast freezer set-ups – but the tendency is general and more likely in an even worse relation.

The above graph illustrates how the energy-consumption is exponentially increasing as air-flow is increased in order to shorten freezing time.

In the example above an air-flow (illustrated on the button axis) of 2,4 m³/s will result in a freezing-time of nearly 36 hours – entailing a total energy-consumption (illustrated on the right axis) of approx., 13 kWh. If air-flow is increased to 6,5 m³/s freezing time (illustrated on the left axis) is reduced to approx. 30 hours while the energy consumption is increasing to 81 kWh.

In other words; By reducing the freezing time with 6 hours or 16%, energy-consumption will be six-doubled

As energy consumption increases exponentially the figures can be even more alarming when looking at a reduction from lets say 31½ hours at 5 m³/s to 27 hours at 6.5 m³/s. In this case the energy consumption will double in order to save 4½ hours or 13% freezing time.

If freezing capacity is a bottleneck in the operation the above might be the only possible strategy, but generally the balance between freezing time and energy-consumption should always be in focus.

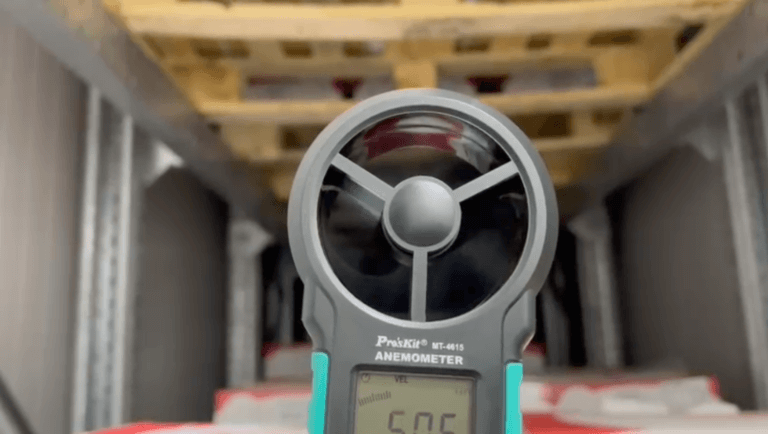

Learn more about freezing strategies in this video

Did you know?

Amongst others, VDKL (Verband Deutscher Kühlhäuser und Kühllogistikunternehmen – The German union of cold storage and logistics) highly recommends using spacers in blast-freezing processes.

FreezeTeq spacer models

There are several solutions when you want to optimize your freezing operation. Have a look at our product selection and find the solution that’ll help you optimise efficiency and reduce your overall costs.

Contact

Learn more about the science behind freezing efficiency and process optimization

Blast Freezing Q&A

Home Blast Freezing Q&A Published as “Blast Freezing Tips” in...

Read MoreReduce energy cost with freezer spacers

Home Reduce energy costs with freezer spacers This may be...

Read More