FREEZETEQ SPACER MODELS

FreezeTeq Air-Flow Spacers can help you improve your food freezing process and thereby lower your energy usage and costs. By optimizing your blast freezing process you not only save money but also lower your CO2 emissions making your product and your company greener.

Combining our unique and patented open-profile spacer designs with our continued focus on assisting the food industry with increased efficiency has made FreezeTeq a well-respected and leading global supplier of freezer spacers.

FreezeTeq spacer models are available in 3 different designs – each with their advantages in their area of operation.

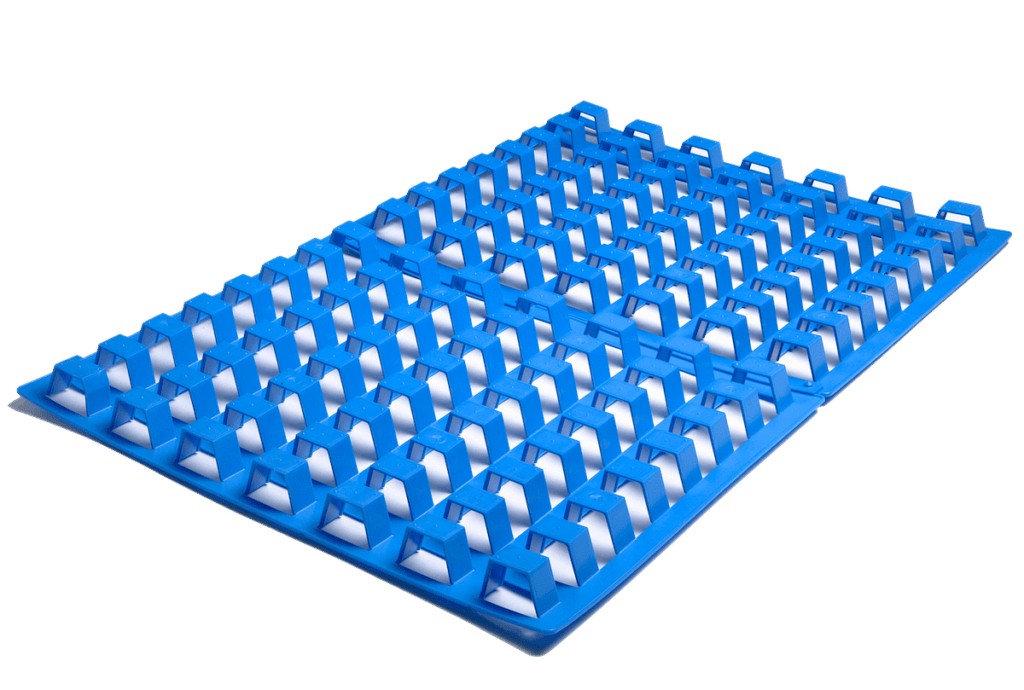

FreezeTeq NFS-I

Freezer Spacer

The first version of FreezeTeq Spacers is designed to allow maximum airflow when blast-freezing food products.

FreezeTeq NFS-II

Freezer Spacer

Designed to be used when transporting pallets with food products to external freezing facilities. Ensures stable loads during transport.

FreezeTeq NFS-III

Freezer Spacer

A single-moulded freezer spacer ensures maximum edge support of the boxes while maintaining maximum airflow between the layers.

Cost-effective

Due to the robust structure of High-Density Polyethylene, our freezer spacer withstands temperatures between -50°C and +90°C and is resistant to acids and chemicals, ensuring a long lifespan, even in the toughest working environments.

Practical

The low weight and open design make it easy to handle and to clean the freezer spacer. The spacers nest easily into each other when not used, thereby taking up a minimum amount of space.

Efficient

The open profiles result in maximum air contact with the stacked layers of products, ensuring faster and more efficient freezing of the whole pallet load.

Environmental

The spacers are manufactured from 100% recyclable materials and can be genuinely recycled at the end of their usable life. Combined with the reduced energy consumption during freezing this benefits the environment.

Did you know?

All FreezeTeq spacers are available in EUR (80 x 120 cm) and EUR2 (100 x 120 cm) sizes.

How do freezer spacers work?

Our unique design facilitates high airflow and good support of the box layers.

Freezer spacers made from recycled HDPE

FreezeTeq Freezer Spacers are made from a polymer called HPDE – high-density polyethylene. It’s a material perfect for the conditions found in a blast-freezing environment. HDPE can withstand high and low temperatures, is form safe, and is resistant to oil and chemicals.

But manufacturing HDPE is a CO2-heavy process. That is why FreezeTeq freezer spacers are made from recycled HDPE material. We use high-quality recycled material to ensure near-to-new quality and our material is typically sourced from the food industry.

Smaller carbon footprint – lower CO2 emissions

From an environmental view, there are huge differences between using recycled and new materials.

Manufacturing freezer spacers from recycled material emit 15 kg CO2 less per spacer than using new material. We think this is a natural choice for a product designed for optimizing energy usage.

Did you know

you can save 50% on your energy consumption with our freezer spacers.

Need help choosing the right spacer for your blast-freezing operation?

FAQ

The relatively low weight and rigid structure of the spacers make them easy to handle manually as well as with robots.

The short answer is no.

It’s all about airflow and box support.

Determined by the design and height of the spacer there is a very big difference in how easily and thus how much air can flow through various spacers. Basically, this is crucial to how effectively a spacer works

Also, the stiffness and the support area of a spacer greatly influence whether your boxes will sink or collapse over the spacer. This again results in damaged boxes, blocked air flow, or even tilted pallet stacks with all the consequent annoyances and expenses

Our designs incorporate more than 30 years of feedback and knowledge from some of the world’s largest and most innovative food companies.

Spacer differences

Although FreezeTeq spacers may be a bit more expensive than average, the 50mm high and extremely open profiles make it the most efficient spacer on the market. Together with the unique support of your box layers, this gives you daily operational savings which will quickly pay for itself and thus become a good investment year after year.

Reduce energy cost

FreezeTeq product selection

There are several solutions when you want to optimize your freezing operation. Have a look at our product selection and find the solution that’ll help you optimise efficiency and reduce your overall costs.